Vehicle electrics

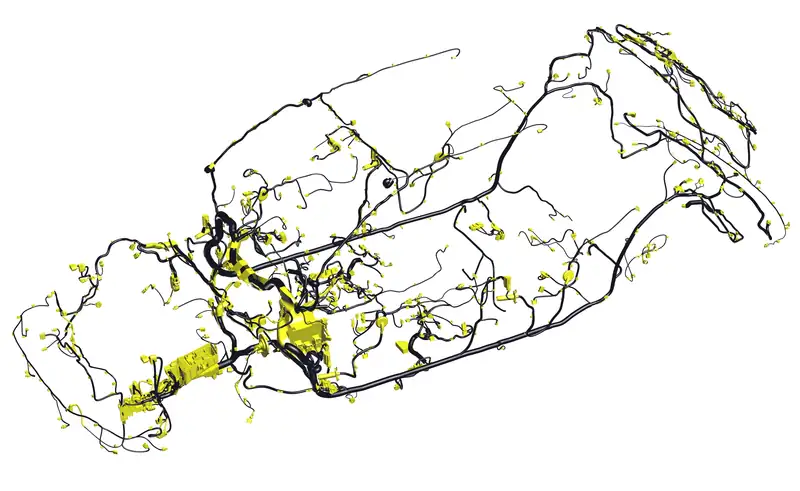

The electrical system is the nervous system of the automobile.

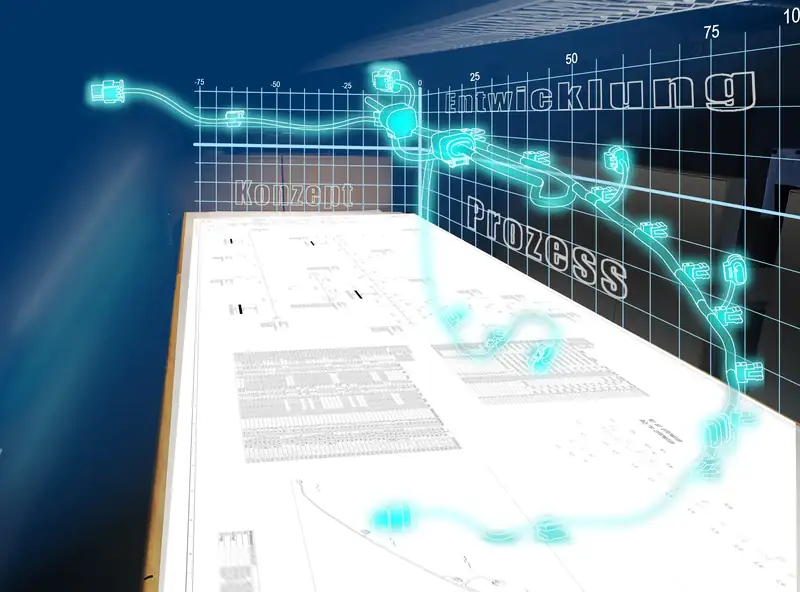

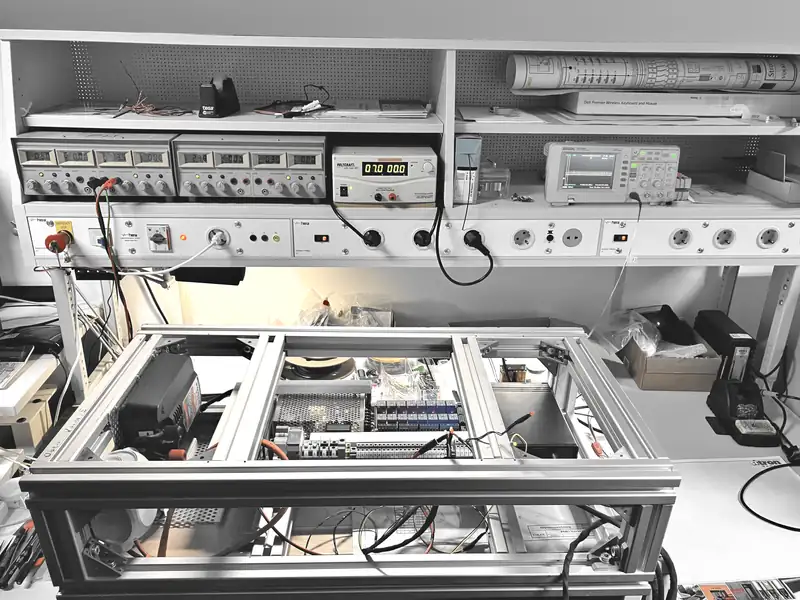

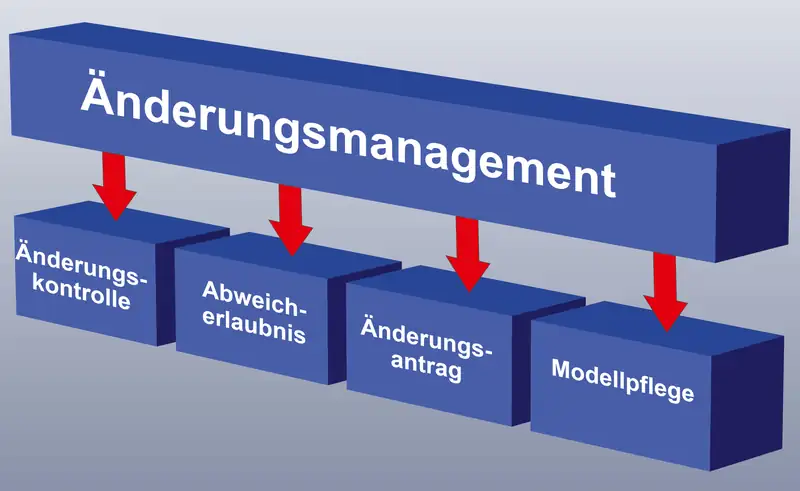

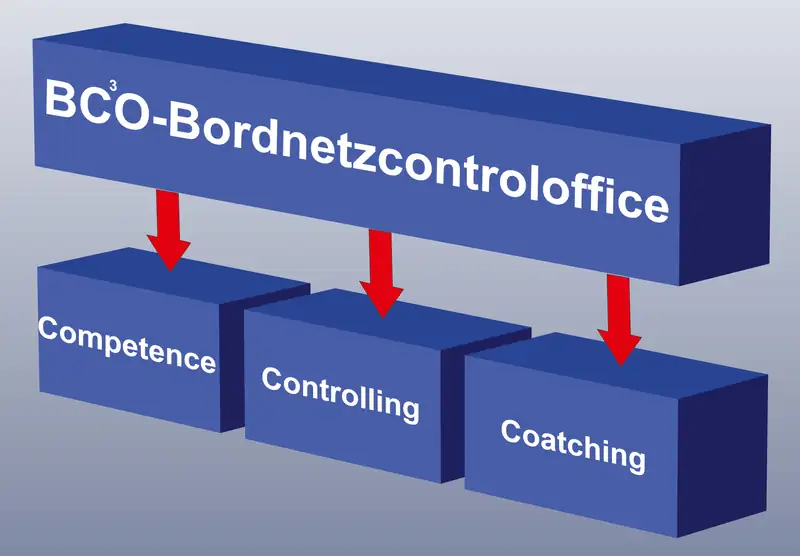

Increasingly sophisticated stability programs, navigation systems, and comfort features are causing the on-board electrical system to swell to many kilometers of cables. Added to this are complex electronics and dozens of control units. Every small car today has more electronics and electrical components on board than the module that landed man on the moon. This requires intelligent planning. Volke offers competent support in development – including: