Vehicle development

We design, develop and present – from your initial idea to series production

We design, develop and present – from your initial idea to series production

In the concept design, we define the boundary conditions for a vehicle project.

Our studio engineers are the link between design and development.

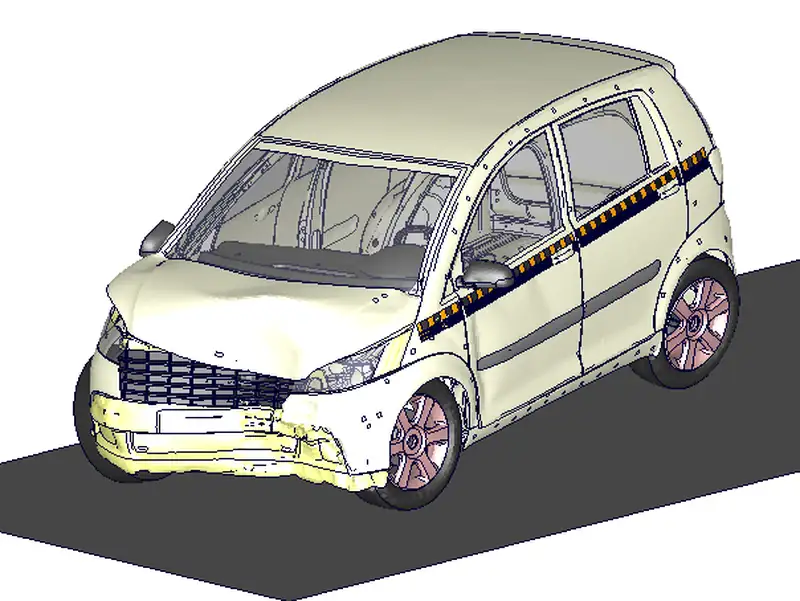

With Surfaces we transform the design concept into technical implementation.

In the design phase, we build sketches into digital models.

Our VR experts have developed their own software solution that enables real-life work in virtual space.

Exterior view

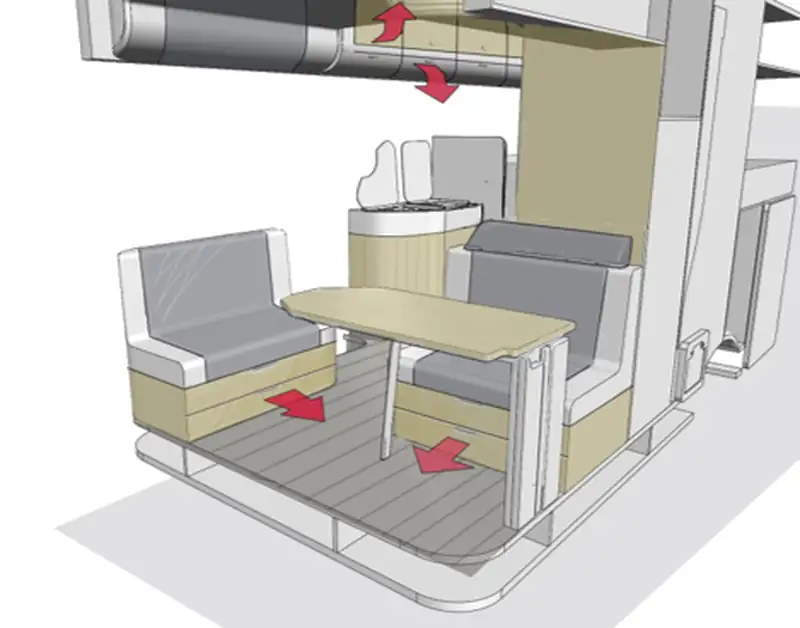

Interior view

Kitchen

Toilet/shower

Sleeping areas

Ambience

Color variants

Outside

We generate virtual geometries using state-of-the-art hardware and software.

We offer:

n addition to specialists for FEM analyses, designers, pre-developers, prototype builders, production planners and manufacturing technicians ensure the suitability of the vehicle for series production in coordination with our clients.

We design and develop:

Functional validation of components and systems.

Eliminating prototypes and hardware shortens development times, saves costs, and delivers long-term solutions for your products and ideas through early virtual design.