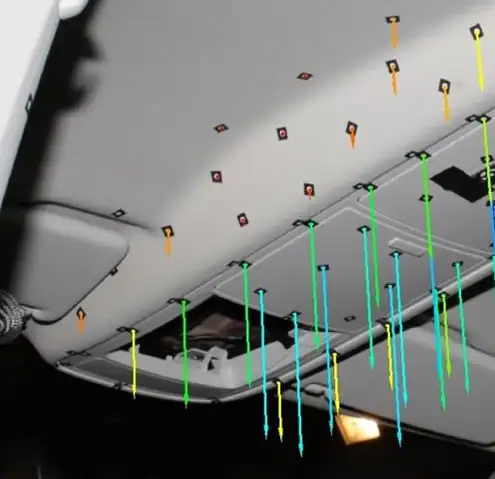

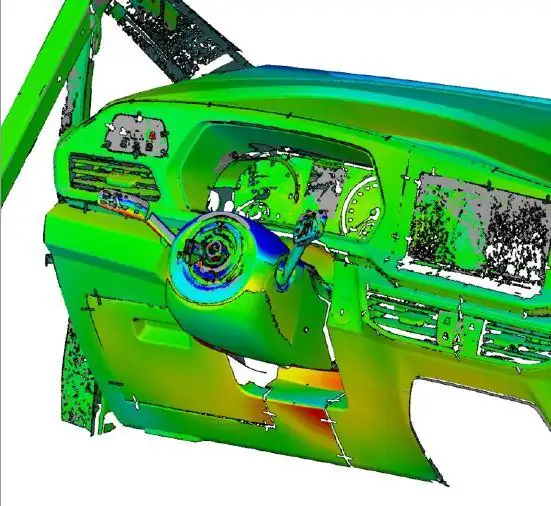

Interior testing

Testing of interior components.

Testing of interior components.

Monitoring and checking of screw connections with regard to:

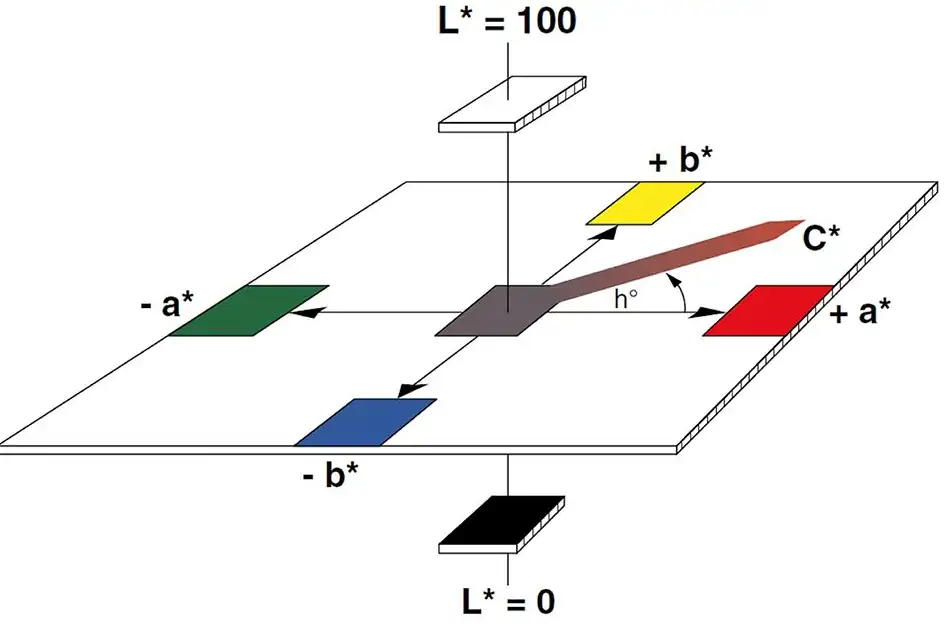

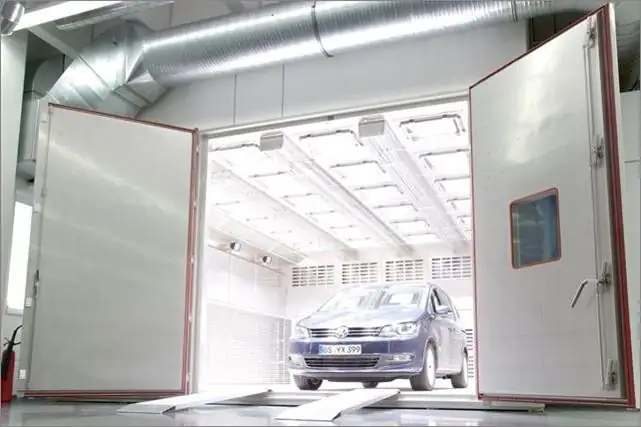

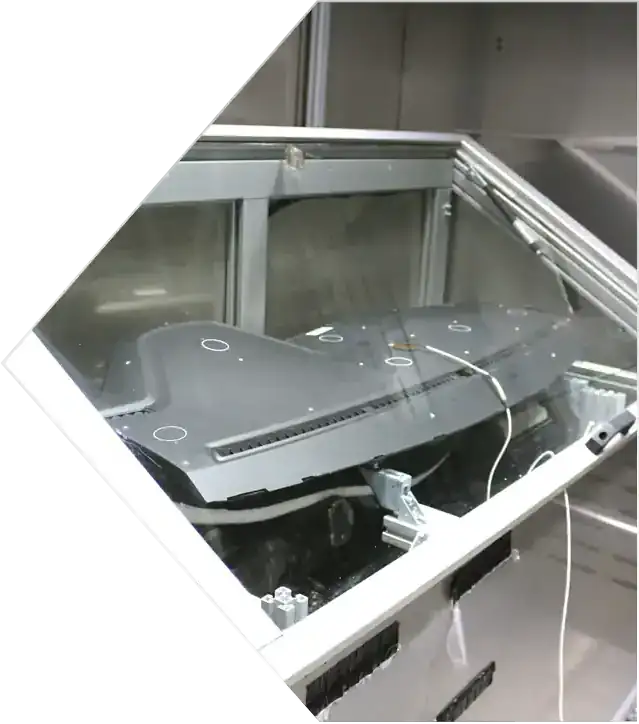

We perform optical, non-contact measurements of test pieces and component assemblies to analyze their interactions.

We work with the following systems: