Testing Environmental Simulation

Environmental Simulation

How do extreme environmental influences affect entire vehicles, components, and assemblies? We explore these questions in our facilities for simulating heat, cold, and dust exposure.

How do extreme environmental influences affect entire vehicles, components, and assemblies? We explore these questions in our facilities for simulating heat, cold, and dust exposure.

Here, desert sunlight is simulated. We conduct tests on entire vehicles and components, such as exterior and interior parts.

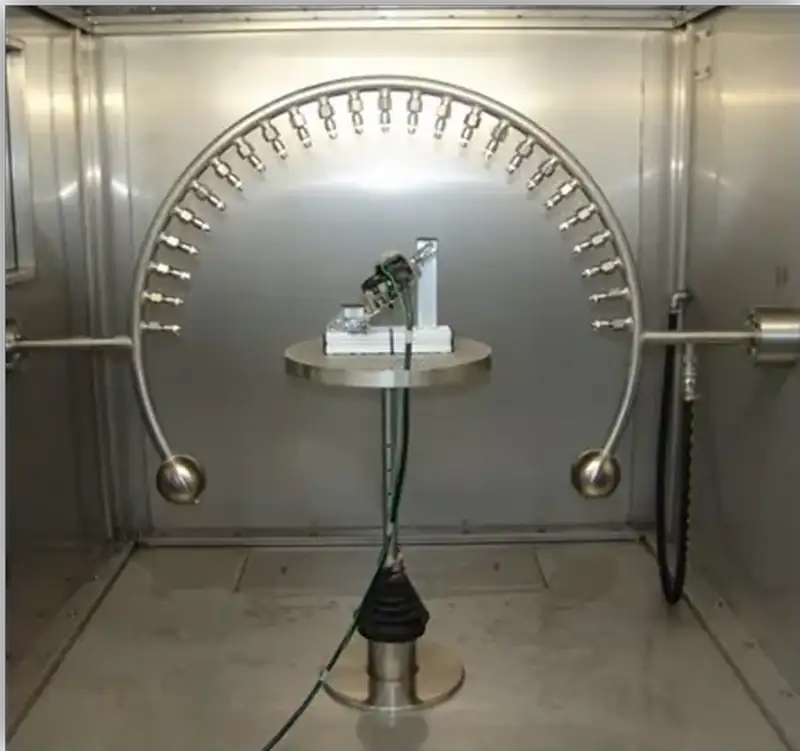

Splash chamber

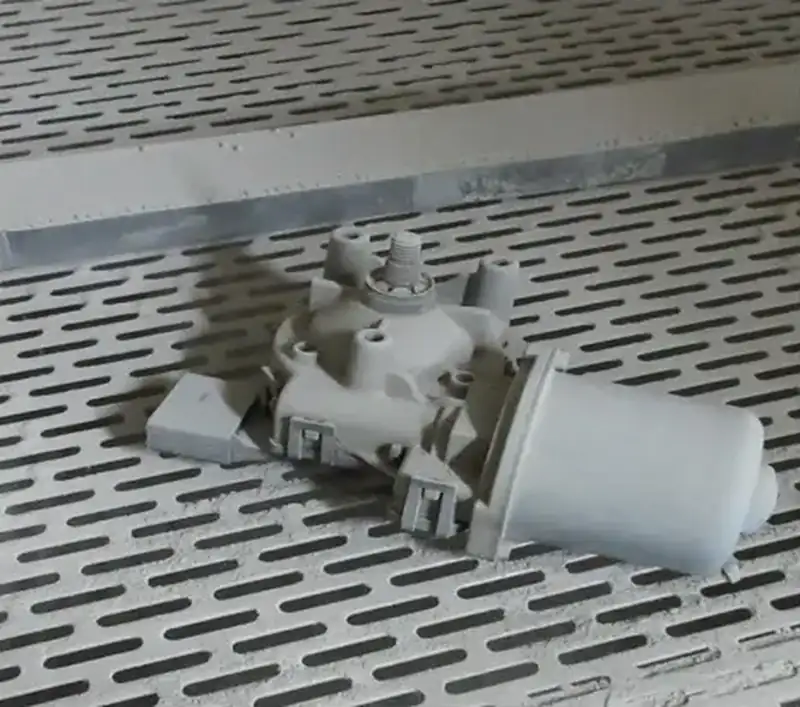

Dust chamber