Safety testing

We conduct tests for our customers to prevent pedestrian injuries as well as to protect occupants.

We conduct tests for our customers to prevent pedestrian injuries as well as to protect occupants.

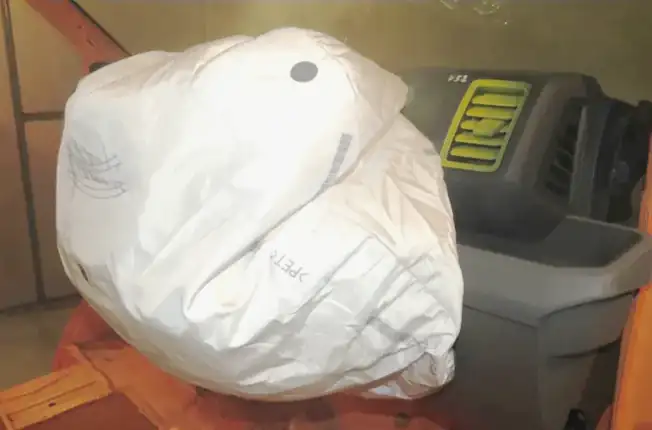

Our responsibilities also include conducting airbag inflation tests, for example, for head, side, driver, and passenger airbags according to the AK-LV guidelines of the automobile manufacturers. We condition the test objects through environmental simulation and test in the temperature range of -40 to +100 °C with video recording using up to six high-speed cameras.

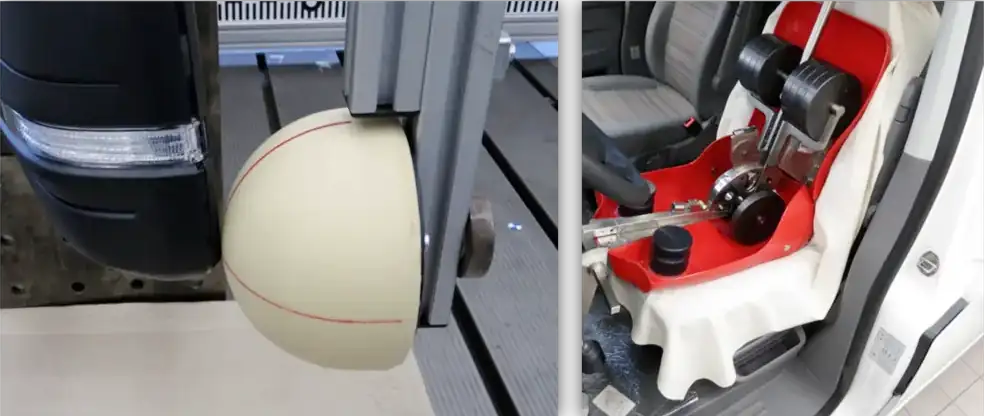

How can we reduce head, leg, and thigh injuries to pedestrians? We conduct tests for this as part of the development of the vehicle's front end, including the bumper, hood, and windshield. We simulate a collision between a pedestrian and a car. Our in-house FEM simulation, design departments, and prototype construction round out the development process. The tests are conducted using a hydraulic high-energy catapult from B.i.A.

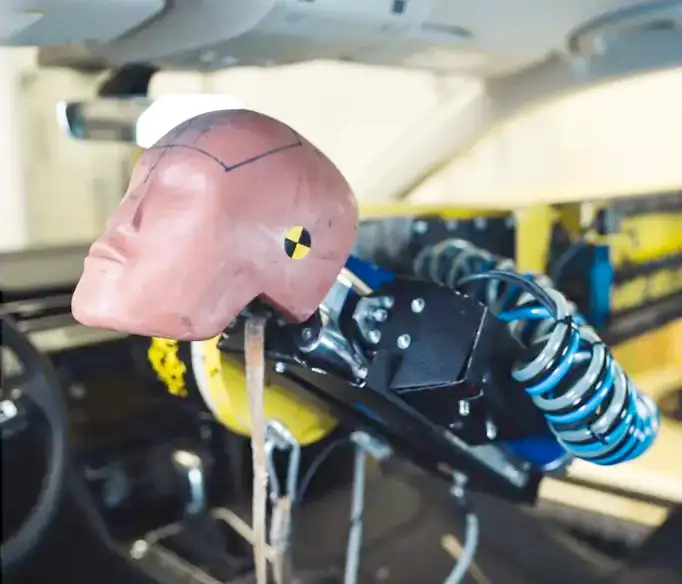

To develop a safe vehicle interior and body structure, we conduct tests on instrument panels, center consoles, headrests, and headliners. The goal is to protect occupants in the event of a crash. The tests are conducted using a hydraulic high-energy catapult from B.i.A.

We conduct tests as part of the development of vehicle interiors. This involves simulating a head impact within the interior. The head impact tests are conducted using a launch device from Microsys.

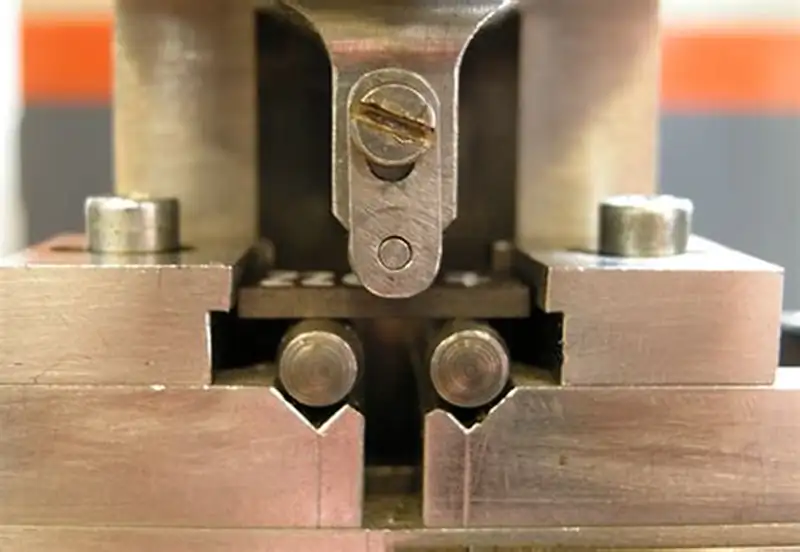

We conduct tests to examine the stability of the materials used in bumpers, spoilers, and plastic mounting supports. This involves simulating a collision while parking, and determining damage at speeds of up to 4 km/h.

We conduct CoP tests to ensure consistent quality of your vehicles. We perform the following tests on-site:

We conduct CoP tests to ensure consistent quality of your vehicles. We perform the following tests on-site.